Automated Inventory: How Drones Eliminate Manual Counts

In our first two articles, we established the ERP as the “conductor” and explored how Augmented Reality (AR) and Autonomous Mobile Robots (AMR) act as “instruments” to revolutionize picking. Now, we address the most dreaded process in logistics: the annual physical inventory.

For 30 years in Automotive, Industrial, and A&D, this has been a slow, expensive, and dangerous operation that often requires a complete operational shutdown. Teams with scanners and scissor lifts spend days manually counting bins, introducing human error and high risk. Drones, a technology that needs no introduction, are now mature and being deployed to solve this specific problem.

The “Lights-Out” Inventory Count

The new process is autonomous. During off-hours or at night, a fleet of autonomous drones flies pre-planned routes through the warehouse. Using computer vision and scanners, they navigate the aisles, scanning pallet barcodes and location barcodes, capturing item, lot, and quantity information from heights impossible to reach safely by hand.

The main benefits are:

- Safety: It completely eliminates the risk of operators working at height.

- Speed: A warehouse that takes a team 3 days to count can be scanned by drones in 5-6 hours.

Real-World Deployments

IKEA (Retail/Distribution)

This is the new standard for large-scale deployment. Since 2021/2022, IKEA has been rolling out a global partnership with Verity for autonomous inventory drones. Their use case is “lights-out” and even “lights-on” counting, with drones operating 24/7 alongside co-workers.

The Result: IKEA achieves near-100% inventory accuracy daily without blocking aisles. This frees up staff from a strenuous, manual, and high-risk task, allowing them to focus on higher-value activities.

More info here: Ikea is elevating human ai powered drone collaboration

Geodis (3PL/Logistics)

Geodis, a global 3PL provider, also uses autonomous drones (in partnership with companies like Deltadrone) for inventory. Their challenge is managing vast, high-bay warehouses for multiple clients.

The Result: They use drones to perform inventory counts outside of business hours. They achieved near-100% inventory accuracy, eliminated the need for weekend work, and crucially, removed the safety risks of having staff operate lifts at high altitudes.

More info here: warehousing and value added logistics expertise

Other Logistics Uses for Drones

While automated inventory is the primary internal warehouse application, drones are heavily used in adjacent logistics functions:

- Yard Management: Flying outside the warehouse to scan and identify containers or trailers in a large yard, replacing manual “yard jockey” checks.

- External Security: Autonomous security patrols around the perimeter of large logistics parks.

- Last-Mile Delivery: The well-known use case of delivering packages directly to consumers.

This is heavily pursued by Walmart and Amazon, treating the drone as a high-speed delivery vehicle.

How Infor LN Manages the Data

A drone is just a high-speed data collector: the real intelligence is in the integration. The drone fleet’s software does not, and should not, become a second inventory system. The ERP remains the “conductor” and the single source of truth.

Here is the integrated workflow:

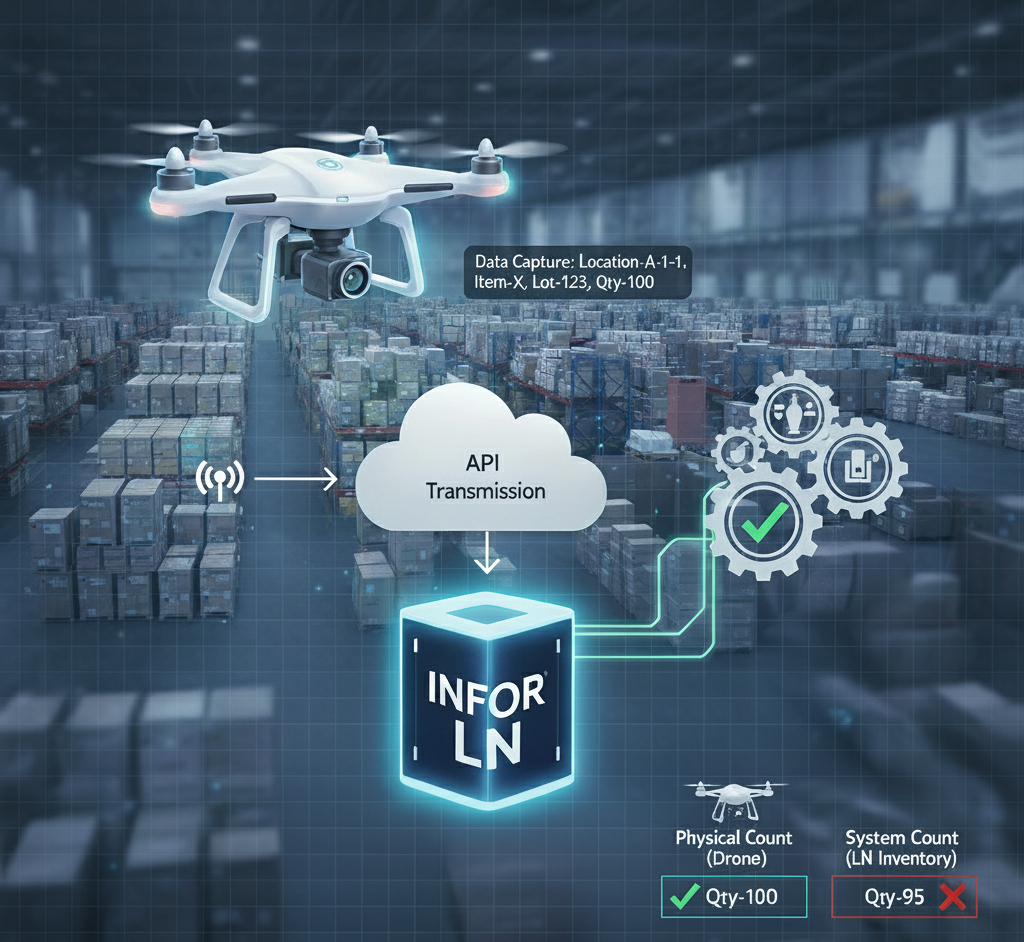

- Data Capture: The drone flies its mission and captures the data: Location-A-1-1, Item-X, Lot-123, Qty-100.

- Data Ingestion: This data file is transmitted via API to Infor LN.

- Automatic Reconciliation: LN ingests this data to automatically populate a Cycle Counting Order. The system then compares the physical count (from the drone) against the system count (LN stock point inventory).

- The Payoff: At 8:00 AM, the Warehouse Manager does not start an inventory count, but reviews a completed count.

The system presents them with the discrepancies to be approved.

The team’s job is reduced from counting 100% of the warehouse to investigating a portion of it.

From Annual to On-Demand

The integration between the ERP and Drones changes the business case entirely. The physical inventory is no longer a costly annual disruption, but rather an on-demand, automated process.

Written by Andrea Guaccio

November 21, 2025