The Factory Conductor: Why Your ERP Needs a Lieutenant on the Shop Floor

(Part 1 of the series: “From Iron to Cloud: The Blueprint for MES Integration”)

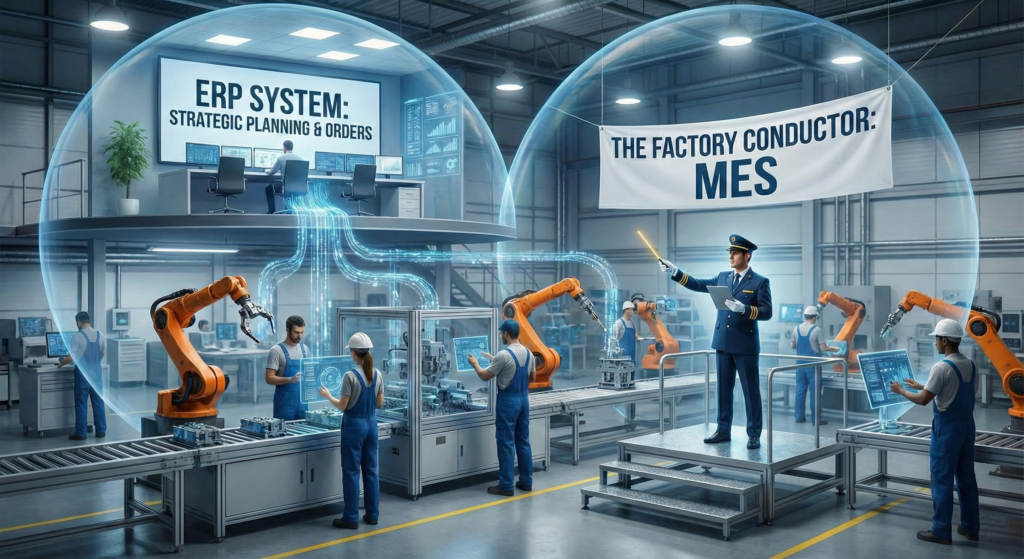

We often confuse the map with the territory. In the high-stakes world of manufacturing – whether it is Automotive, Aerospace, or Industrial Machinery, the ERP is your map. It handles the grand strategy, the standard costs, the procurement forecast, and the long-term planning. It is the strategic backbone of the company.

But down on the shop floor, where metal meets the cutting tool, the map is not enough. You need a MES (Manufacturing Execution System).

If the ERP provides the plan, the MES manages the reality. It coordinates workflows over the noise of the machines, reacts to a broken tool in real-time, and ensures that resources (operators and robots) are perfectly synchronized.

In this first chapter of “From Iron to Cloud,” we are going to debunk the myth that “My ERP can do production,” explain why Excel is the enemy of efficiency, and define exactly where Infor LN ends and the MES begins.

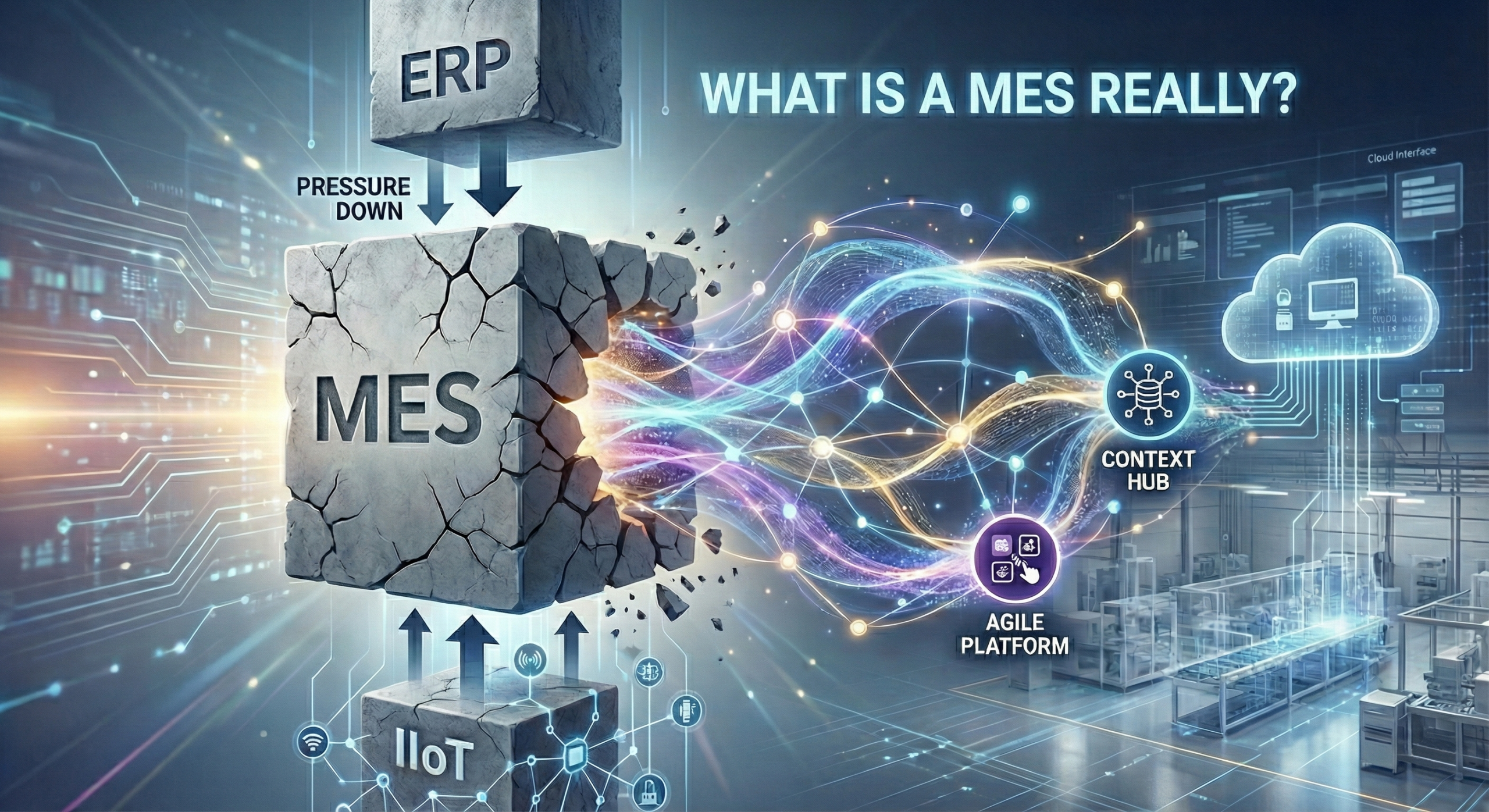

The Identity Crisis: What is an MES really?

If we look at the purist definition from the ISA-95 standard, the MES occupies Level 3. It sits comfortably between Level 4 (Business Planning/ERP) and Level 2 (SCADA/PLC/Control Systems).

Many companies try to stretch their ERP down to Level 3. They print paper travelers from Infor LN, hand them to operators, and ask them to manually log hours into a terminal at the end of the shift. This is not execution, but merely administration.

A true MES does not just record what happened, but it orchestrates what is happening right now. It is the difference between reading a weather report from yesterday and looking out the window during a storm.

Market Examples

To make this concrete, we are not talking about abstract concepts. When we speak of MES, we refer to specialized platforms built for the 24/7 battlefield of the shop floor. Depending on your industry and size, you might encounter:

- The Global Titans: Massive suites like Siemens Opcenter, Rockwell Automation’s Plex, or Dassault DELMIA Apriso. These are the heavyweights often found in Tier 1 Automotive and Aerospace.

- The Infor Native: Infor MES (formerly Lighthouse). While this is often seen as the natural choice for Infor LN users, it is important to note that the “single-vendor” advantage is becoming increasingly marginal. As I’ve explained on my article The Composable ERP, thanks to modern, robust APIs provided by Infor, integrating third-party products is now seamless. This means you can choose the best tool for your specific needs without sacrificing integration quality compared to a native product.

- The Agile Challengers: Globally recognized modular platforms like Parsec TrakSYS or the no-code disruptor Tulip. These often provide faster ROI and flexibility compared to the monolithic giants, making them popular in dynamic mid-to-large enterprises.

Choosing the right Lieutenant is as critical as choosing the General.

The Core Four: Beyond Tracking Time

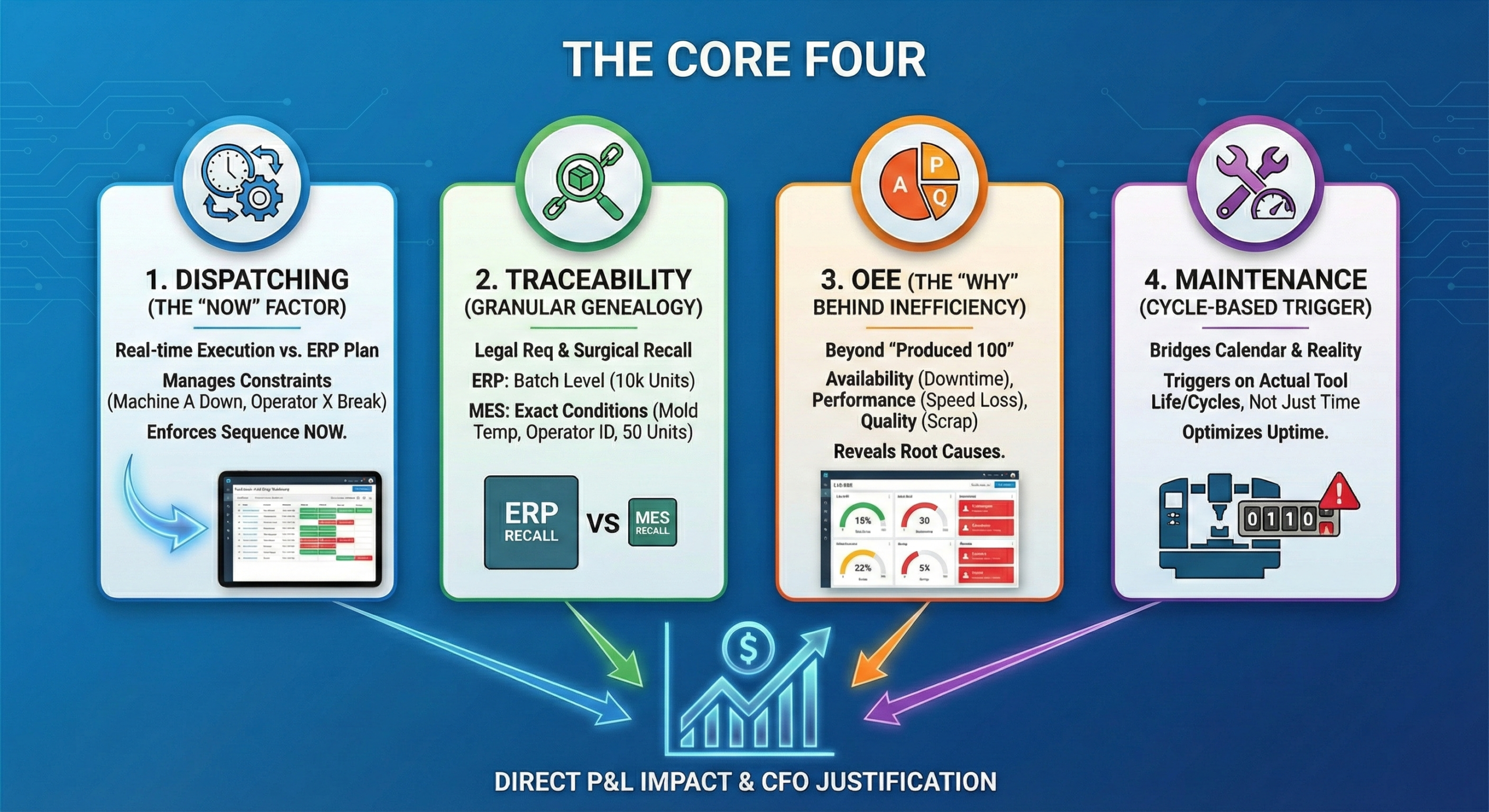

To justify the investment to a CFO, you need to move beyond generic buzzwords. An MES relies on four pillars that directly impact the P&L.

1. Dispatching

Infor LN runs MRP and generates a production plan. It tells you that Production Order 1001 is due next Friday. Great. But the MES takes that order and breaks it down. It knows that Machine A is currently undergoing maintenance and that Operator X (who has the specific certification for this weld) is on break. The MES decides who does what, where, and exactly now. It enforces the sequence based on real-time constraints, not infinite capacity planning.

2. Traceability

In sectors like Aerospace and Defense, it is a legal requirement. When a recall hits, you cannot afford to guess. The ERP tracks inventory, but often at a transactional level (Receipt à Issue). The MES tracks the genealogy. It answers the granular questions: “Which specific batch of resin was used in the injection molding process for Serial Number X, what was the temperature of the mold at that exact second, and which operator signed off on the quality check?” This is the difference between recalling 10,000 units (ERP granularity) and recalling the 50 suspect units (MES granularity).

3. OEE

Overall Equipment Effectiveness (OEE) is the holy grail of manufacturing KPIs, calculated by multiplying Availability, Performance, and Quality.

- ERP View: “We produced 100 pieces in 8 hours.”

- MES View: “The machine was down for 2 hours (Availability), ran at 85% speed when up (Performance), and scrapped 5 pieces (Quality).”

Without an MES, you know that you are inefficient, but you rarely know why.

4. Maintenance Management

While Infor LN has excellent Service and Maintenance modules, the MES bridges the gap between the calendar and the cycle count. It triggers maintenance not just because “it’s Tuesday,” but because the tool life counter on the CNC machine just hit the threshold.

The Excel Hell and the Business Case

Why do so many companies hesitate to implement an MES? Because they believe Excel is free. This is not just a consultant’s anecdote, but a statistical reality. According to a December 2025 study by IoT Analytics, approximately 54% of global manufacturing operations still rely on a “pen & paper” or spreadsheet-based approach to manage their shop floor. Even in companies running top-tier ERPs, industry data suggests that nearly half of detailed scheduling is exported and managed in offline files that are invisible to the rest of the organization.

The hidden cost of this “Shadow IT” approach is staggering:

- Data Latency: decisions are made on Friday based on data from Tuesday. By the time you realize you are behind schedule, it is too late to recover.

- WIP Inflation: without real-time visibility, managers flood the floor with orders to “keep everyone busy,” driving up Work In Progress inventory and tying up cash.

- The Post-Mortem Culture: meetings are spent arguing about whose data is correct rather than solving problems.

The Business Case for an MES is simple: eliminate the lag. By digitizing the shop floor, you move from “Post-Mortem Analysis” to “Real-Time Intervention.” You stop analyzing why the patient died and start performing surgery while they are still alive.

Stop trying to make ERP do the MES’s job

Infor LN is a beast. It is incredible at managing the financial impact of your operations, calculating standard costs, and ensuring your supply chain is fed. But it is not designed to talk to a PLC every 500 milliseconds. Even with standard Shop Floor Control parameters (tisfc) active, it is not designed to lock a machine if a quality check fails.

When you customize your ERP to act like an MES, you create a monster. You end up with a system that is too slow for the shop floor and too cluttered for the finance team.

The Golden Rule:

- The ERP plans the War. It decides what products will conquer the market, how much they should cost, and where the materials come from.

- The MES fights the Battle. It deals with the mud, the breakdowns, the shift changes, and the chaotic reality of making things.

In the next article, we will tackle the Gordian Knot: how do we actually integrate Infor LN and an MES? We will dive into the technical details of Master Data ownership, BODs, and the nightmare of handling Engineering Changes (ECOs) when the line is already running.

Written by Andrea Guaccio

January 30 2026