AMR in the Smart Warehouse

In many large facilities, operators spend over 50% of their shift simply walking: this is non-value-added time.

While our last article gave operators AR “superpowers”, this post tackles that waste at its source using Autonomous Mobile Robots (AMR). But first, you must understand why an AMR is not just a smarter AGV.

AGV vs. AMR: Differences Explained

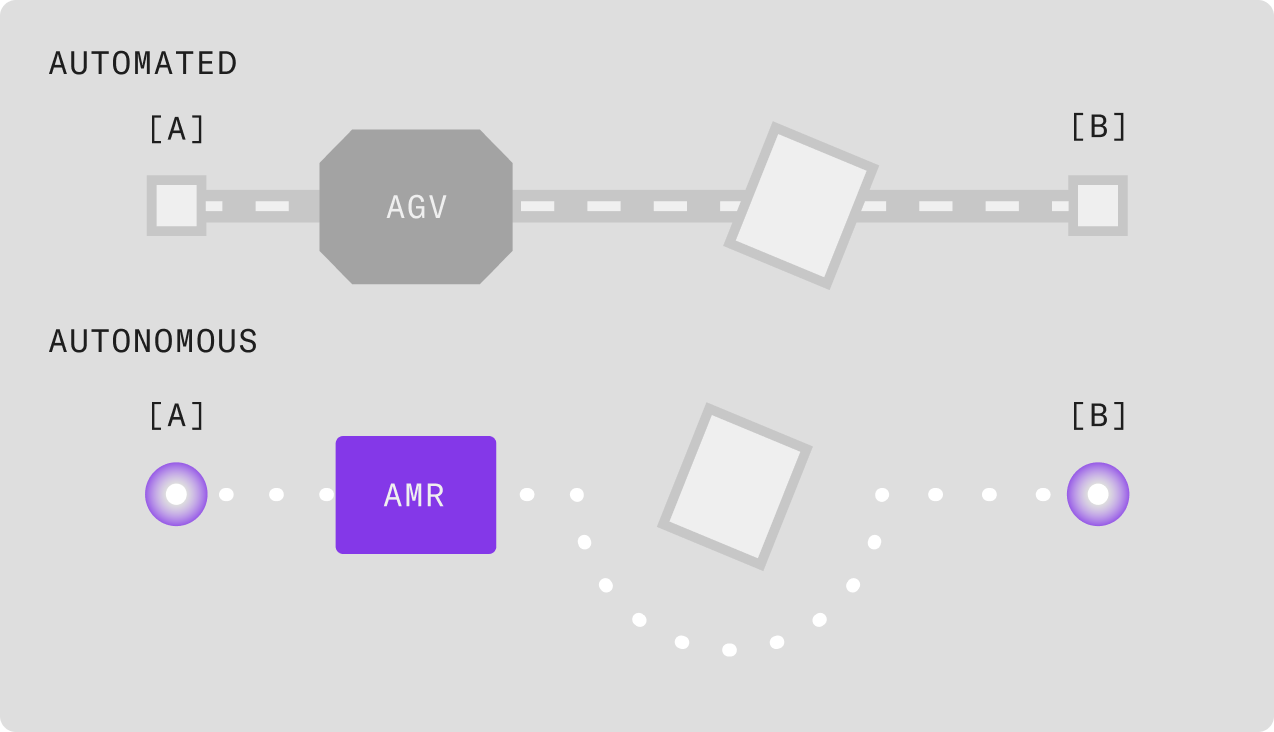

It’s crucial to distinguish between the two primary types of warehouse robots, as their impact and integration differ significantly.

- Automated Guided Vehicles (AGV):

- Navigation: AGVs rely on fixed infrastructure for guidance. They follow pre-defined paths, typically magnetic stripes on the floor, wires, or reflective tape.

-

- Flexibility: they are inflexible, their paths are set. If an obstacle (like a pallet or a forklift) blocks the path, the AGV stops and waits for the obstacle to be cleared. Re-routing or changing the warehouse layout is a major project, requiring new infrastructure.

-

- Use Case: best suited for highly repetitive, simple, and unchanging tasks, like moving finished goods from a production line to a static dispatch area.

- Autonomous Mobile Robots (AMR):

- Navigation: AMRs navigate dynamically using advanced (SLAM – Simultaneous Localization and Mapping) technology, Lidar, and cameras. They create and store maps of the facility and understand their environment.

-

- Flexibility: they are highly flexible. If an AMR encounters an obstacle, its software instantly calculates a new route to bypass it, just as a human would. Deployment is faster, as they don’t require structural changes to the floor.

-

- Use Case: ideal for dynamic environments like picking, sorting, and “goods-to-person” workflows, where routes and demands change constantly.

Market data shows a clear trend: while the AGV market is mature, the AMR market has been growing at a rate exceeding 30-40% CAGR, with tens of thousands of AMRs now deployed globally, a number rapidly accelerating as companies prioritize flexibility. AMRs completely flip the operational script from people-to-goods to goods-to-person. The operator no longer walks but becomes a high-efficiency picker at a fixed station, and the inventory comes to them.

How Infor LN Orchestrates the Goods-to-Person

AMRs execute a precise plan. As established, the flow is orchestrated by the ERP, which acts as the Conductor giving the initial command.

- Command (ERP): Infor LN generates the demand. This could be a Picking List for a sales order, or a material requisition from a Production Order.

- Transmission (ION): LN sends this mission (e.g., “I need 10 units of Item X”) via ION.

- Orchestration (WMS + Fleet Manager): this mission is received by the WMS, which talks to the Fleet Manager software (the robot’s direct brain). The Fleet Manager identifies the exact shelf holding Item X and, crucially, optimizes the queue.

- Execution (AMR): the Fleet Manager dispatches the nearest available AMR. The robot navigates autonomously to the shelf, lifts it, and brings the entire shelf to the operator’s fixed picking station.

- Action: the operator sees a “put-to-light” signal at their station, telling them which item and quantity to pick from the shelf that just arrived.

- Confirmation: the operator picks the 10 units, confirms the pick, and the AMR returns the shelf.

This confirmation updates Infor LN’s inventory in real-time. While this is happening, the Fleet Manager has already dispatched another AMR with the next order, which arrives at the station seconds later. The operator never waits; they are focused 100% on the value-added task: picking.

Real-World Examples: From Kiva (Amazon) to Modern Integrators

The Pioneer & The Evolution (Amazon Robotics)

Amazon effectively created this market by acquiring Kiva Systems in 2012. Kiva’s iconic orange robots proved the goods-to-person model, but they operated in caged-off, human-excluded zones. The modern evolution is Proteus, Amazon’s first fully autonomous robot.

Proteus is designed to navigate and work safely alongside humans, without needing restricted zones. It autonomously picks up and moves heavy “GoCarts” (trolleys) across the warehouse floor, collaborating with the human workforce. This represents the next leap: collaborative, autonomous-driven logistics.

The Modern Integrator (KION / Dematic)

This is more representative of how a non-Amazon company would deploy this. Integrators like KION Group (which owns Dematic) provide these complete goods-to-person solutions. The workflow is identical: the AMR fleet is managed by a WMS (often integrated with the ERPs like LN), bringing shelves to put-to-light stations.

The ROI: How AMRs Double Picking Productivity

The ROI calculation is straightforward: by eliminating the 50% non-value-added “walk time,” you effectively double the operator’s capacity for value-added work (picking). This is how integrators report 2x or 3x increases in picking productivity (lines per hour).

To know more, click here.

Next Up: we’ve optimized the pick and the travel, but what about the other major operational time sink? Manual, full-stop inventory counts.

Next, we’ll analyze Drones.

Written by Andrea Guaccio

November 18, 2025