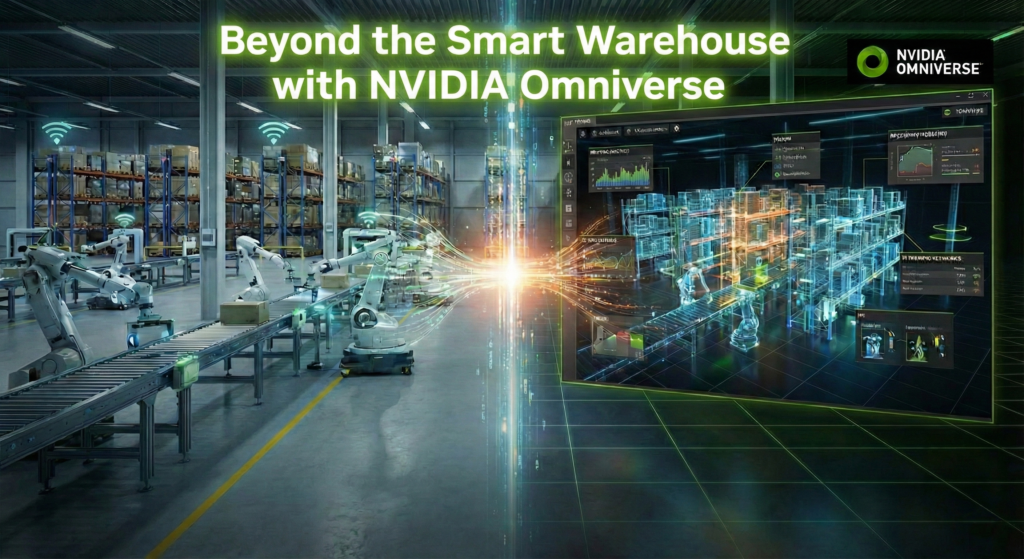

Warehouse Digital Twin Simulation: Beyond the Smart Warehouse with NVIDIA Omniverse

In our main series, we discuss how to optimize existing warehouse operations using AR, AMR, and Drones.

However, a significant opportunity lies in identifying operational bottlenecks before construction begins or before new equipment is installed.

This capability is provided by the Industrial Metaverse, and inside this spinoff article we’re take a look of what does it means for the industry.

Through the partnership between industrial giant Siemens and AI leader NVIDIA, the industry is moving from static 3D models to physics-based Digital Twins.

What is NVIDIA Omniverse?

Omniverse is an Operating System for 3D, built on three core technologies that distinguish it from standard visualization tools:

The “HTML of 3D”: Understanding USD

Historically, the biggest barrier to creating a true Digital Twin was file incompatibility. The architect uses Revit, the conveyor supplier uses Siemens NX, and the robot manufacturer uses proprietary CAD software.

Bringing these together usually meant hours of painful file conversion and significant data loss.

NVIDIA Omniverse solves this with USD (Universal Scene Description).

Think of USD as the “HTML of 3D worlds.” Originally invented by Pixar, it allows different software tools to “publish” their data into a single, shared virtual environment in real-time.

This means we aren’t just looking at a static snapshot.

If the facility manager moves a wall in Revit, the Digital Twin updates instantly.

If the logistics engineer tweaks the conveyor speed in their specialized tool, the simulation reflects it immediately.

It creates a single source of truth for the physical layout.

Beyond Animation: The Power of PhysX

Most warehouse simulations we’ve seen in the past were essentially cartoons: visual representations where a box moves from A to B because a script tells it to.

They rarely accounted for the messy reality of physics.

Omniverse uses NVIDIA PhysX, a high-fidelity physics engine.

In this environment, objects have mass, friction, velocity, and gravity. This level of fidelity allows us to test safety margins and mechanical limits virtually.

The Secret Weapon: Synthetic Data

Perhaps the most futuristic application of this technology is training AI models.

Modern warehouses are full of optical sensors and Autonomous Mobile Robots (AMRs) that need to “see” and understand the world.

Training these robots typically requires thousands of real-world photos of boxes, pallets, and labels.

This is slow, expensive, and requires the physical goods to be present.

With Omniverse, we can use Synthetic Data Generation.

We can spawn a digital 3D model of a product and replicate it 10,000 times in the virtual warehouse, changing the lighting, angle, and occlusion (e.g., partly hidden behind a pillar) instantly.

We then use these “fake” but physically accurate images to train the robot’s AI brain.

By the time the physical robot arrives on site, it has already “seen” millions of scenarios in the Digital Twin and is ready to operate on Day 1.

The Value of Simulation

Optimizing a warehouse traditionally involves significant planning and potential reconfiguration costs.

High-fidelity simulation allows for virtual testing of multiple scenarios:

- Layout Optimization: Comparing different racking configurations to determine the most efficient travel paths.

- Stress Testing: Simulating peak volume scenarios (e.g., Black Friday) to identify congestion points at receiving docks or packing stations.

- Robot Training: Training AMRs within the digital twin allows them to learn the facility layout and navigation logic prior to physical deployment.

Watch it in Action & Official Sources

See how these technologies are applied in real-world scenarios:

- Official Partnership Page: Read the official details on how Siemens and NVIDIA are building the Industrial Metaverse.

- Siemens & NVIDIA Partnership Video: Integrating factory data with AI visualization.

- Amazon Robotics: Utilizing Digital Twins for package flow optimization and robot training.

- Physics Demo: A technical demonstration of physics interactions in a warehouse simulation.

The Role of the ERP: The Data Source

The Digital Twin requires accurate data to function effectively.

As I explored in my previous analysis, Your ERP Shows What Happened. The Digital Twin Shows What’s Next, the distinction is critical:

- The ERP (e.g., Infor LN) records the past and manages the present (Historical Data, Order Profiles, Inventory Logic).

- The Digital Twin simulates the future, using that ERP data to predict outcomes before they occur.

Without the solid foundation of ERP data, the Digital Twin is just a theoretical model. Together, they allow you to move from reactive management to predictive optimization.

In Conclusion, this technology allows Logistics Directors to predict operational outcomes with high accuracy.

By identifying issues during the design phase, organizations can ensure their facilities are optimized before physical operations commence.

Written by Andrea Guaccio

December 3, 2025