Blog Articles

-

When Software Writes Itself: The Illusion of the Homebrew ERP

-

The Cognitive Factory – AI, ESG & The Future of MES

-

The AI Exodus: Why the Builders Don’t Trust the Building

-

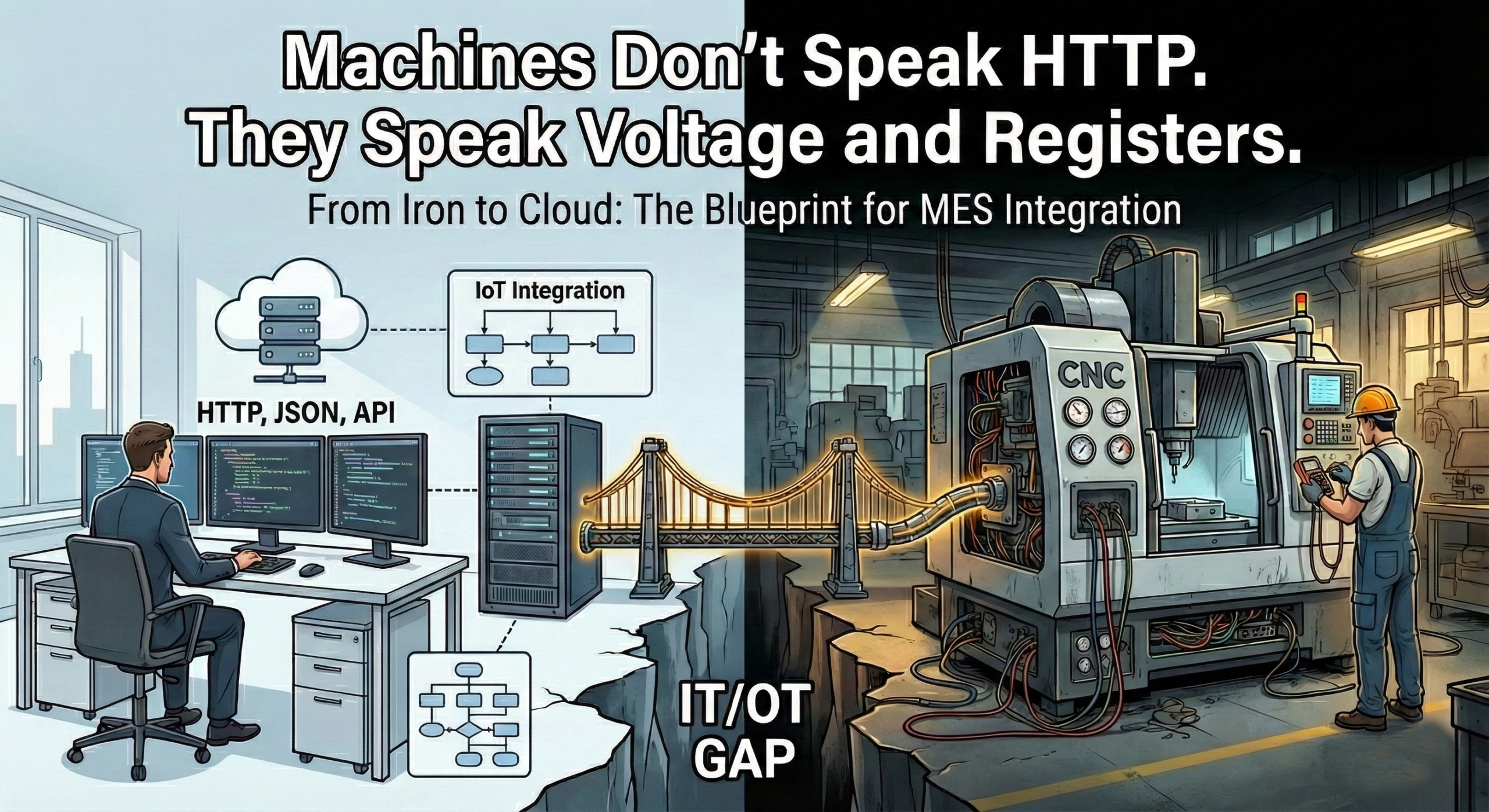

Machines Don’t Speak HTTP. They Speak Voltage and Registers

-

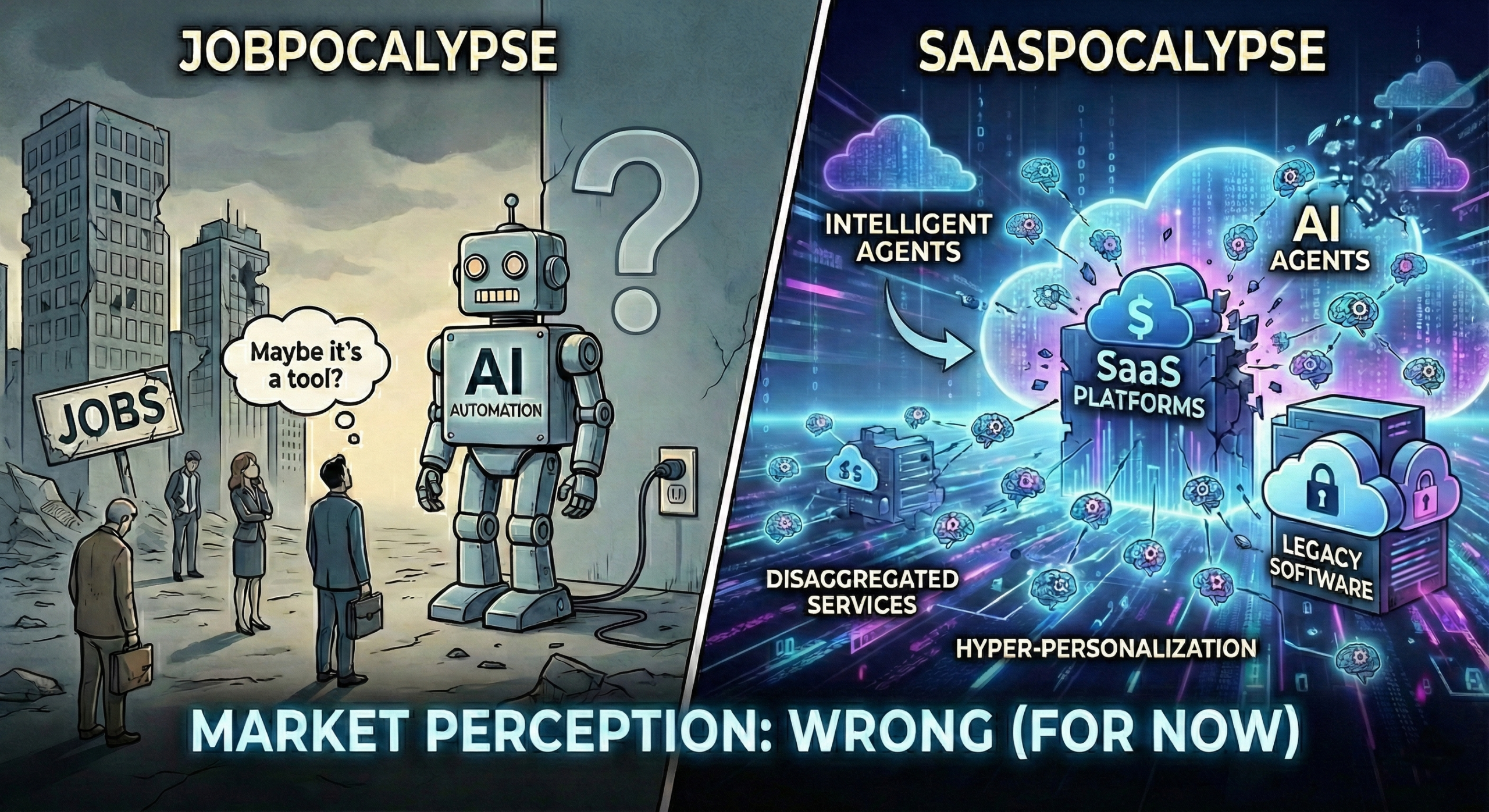

AI Agents vs SaaS Business Model: Why the Saaspocalypse is Wrong

-

The Gordian Knot: Syncing Infor LN and MES Without Creating Data Hell

-

The Factory Conductor: Why Your ERP Needs a Lieutenant on the Shop Floor

-

From Iron to Cloud: The Blueprint for MES Integration

-

The Algorithm Auditor: The New Role of the ERP Expert

-

The AI Killer: Why Dirty Data Will Bankrupt Your Agent

-

The Agent Delusion: Why Your ERP Isn’t Ready for Autopilot (Yet)

-

Generative BI: Talking to Your Data

-

AI vs. GenAI vs. Agentic AI: Decoding the Infor Landscape

-

The ERP Intelligence Evolution: From Static Data to Autonomous Agents

-

Warehouse Digital Twin Simulation: Beyond the Smart Warehouse with NVIDIA Omniverse

-

p2-i Widgets for Infor LNCE: A Guide to Actionable ERP Data

-

Automated Inventory: How Drones Eliminate Manual Counts

-

AMR in the Smart Warehouse

-

Augmented Reality

-

Smart Warehousing Trends

-

The ERP That Doesn’t Feel Like an ERP

-

Cloud ERP: Redefining Customization Through Extensibility

-

The New Role of the Infor LN Consultant

-

Your ERP Shows What Happened. A Digital Twin Shows What’s Next